By Anaïs Diez

Why a perforation tool? A technical challenge in paper conservation

In paper conservation, depending on the treatment, precisely cutting various types of paper can be a critical step. Infilling losses on paper supports, for instance, often requires great precision, especially when adapting the infill to translucent paper or using feathered edges that seamlessly blend with the original support.

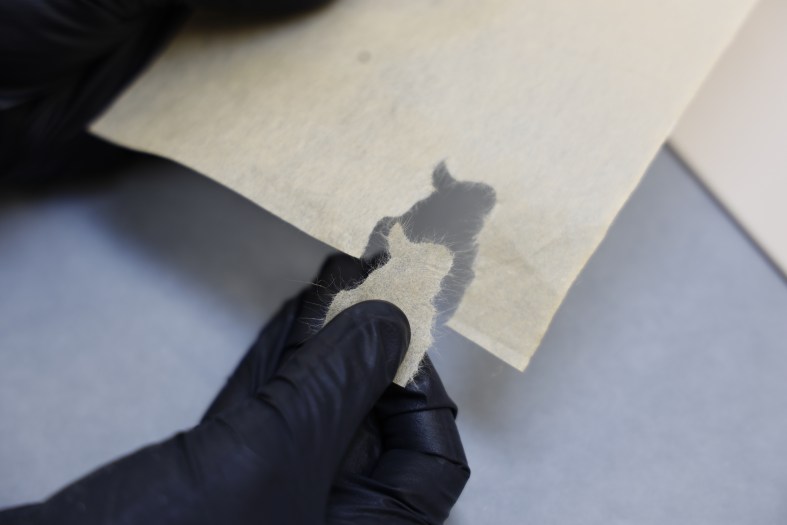

Traditionally, infill shapes are cut using manual tools such as a scalpel or punch, depending on the desired outcome. Perforation involves mechanically puncturing the paper at regular intervals along a predefined contour. This trail of perforations weakens the fibres locally, enabling them to be gently torn apart using a damp brush, producing soft, irregular edges. This technique has long been used by paper conservators to avoid sharp, mechanical cuts. The feathered edges help with adhesion and create a visually discreet transition between the fill and the original support. They also improve bonding stability and mechanical continuity of the support. However, each hole must be made individually, which becomes tedious and time-consuming in large-scale treatments or when working with oversize formats.

In search of efficiency

The need for greater efficiency became particularly pressing in 2023 during a conservation project at the Musée des Arts Décoratifs involving the architectural drawings of Alfred Nicolas Normand. The collection includes over 475 drawings, of which 160 were executed on highly damaged tracing paper requiring substantial infill work. The need for precision, combined with the volume of the work, prompted the search for a faster, more efficient and less physically demanding alternative to manual perforation.

Conservators often repurpose tools from other fields, adapting them to meet specific technical needs. My initial inspiration came from the New York Public Library, where conservators Grace Owen-Weiss and Barbara Goldsmith developed a paper perforation pen by repurposing a nose hair trimmer, adding a needle to convert it into a mechanical piercer. My goal was to find a more reliable alternative that could be integrated into conservation practice without complex modifications. I wanted a tool that was compact, portable, and designed for repetitive, controlled motion. Digital cutting machines with an integrated scanner offer precision, but they are not suited for mobile or in-situ work. Then I thought of a tattoo pen. Although designed for skin, this tool features a mechanism that is surprisingly well-suited to conservation needs.

The rotary tattoo pen: operation and adaptation for conservation

Rotary tattoo machines operate on an electromechanical principle, converting rotary motion into linear reciprocating motion. The needle is mounted in a cartridge and oscillates at high frequency, controlled by the input voltage (typically between 5 and 12 volts). Tattoo pens are powered by external power sources or internal rechargeable batteries, and some feature a display indicating voltage and battery level. This allows for precise control over the speed and force of the needle.

Using a rotary tattoo pen for paper perforation offers several significant advantages in conservation. First, it allows precise and consistent control over perforation density (puncture spacing) by adjusting the voltage, and therefore the needle speed. This level of control is not possible with manual perforation, which depends entirely on the operator’s hand movements. Thanks to the wide range of needle configurations available, the size and arrangement of the punctures can be adapted to suit the characteristics of the paper (brittleness, weight, tear resistance), allowing for a highly tailored approach. Additionally, this method significantly reduces physical strain on the conservator’s body, as the perforation is motorised. The user no longer needs to apply repeated pressure, which reduces muscle fatigue. On a technical level, the tool offers enhanced precision regardless of the fineness of the movement, thanks to its stable mechanical action. It’s also fast, taking only a few seconds to prepare a paper infill. This makes it invaluable for large-scale treatments or oversized works.

Technical criteria for selecting and using a tattoo pen in conservation

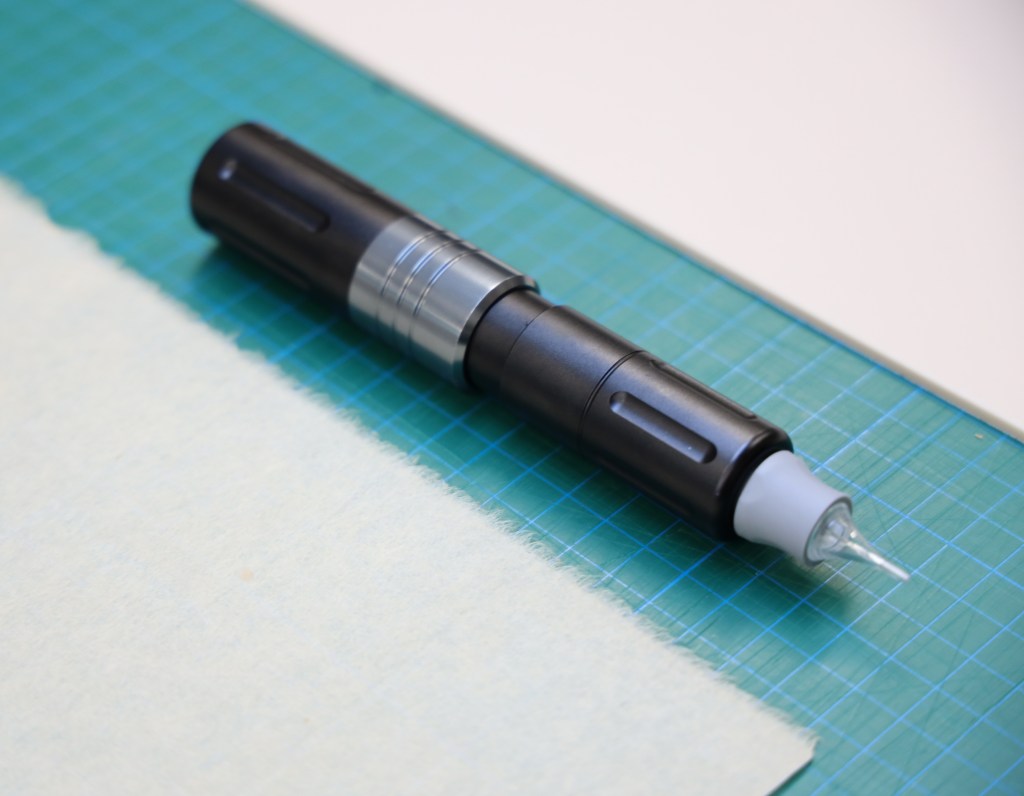

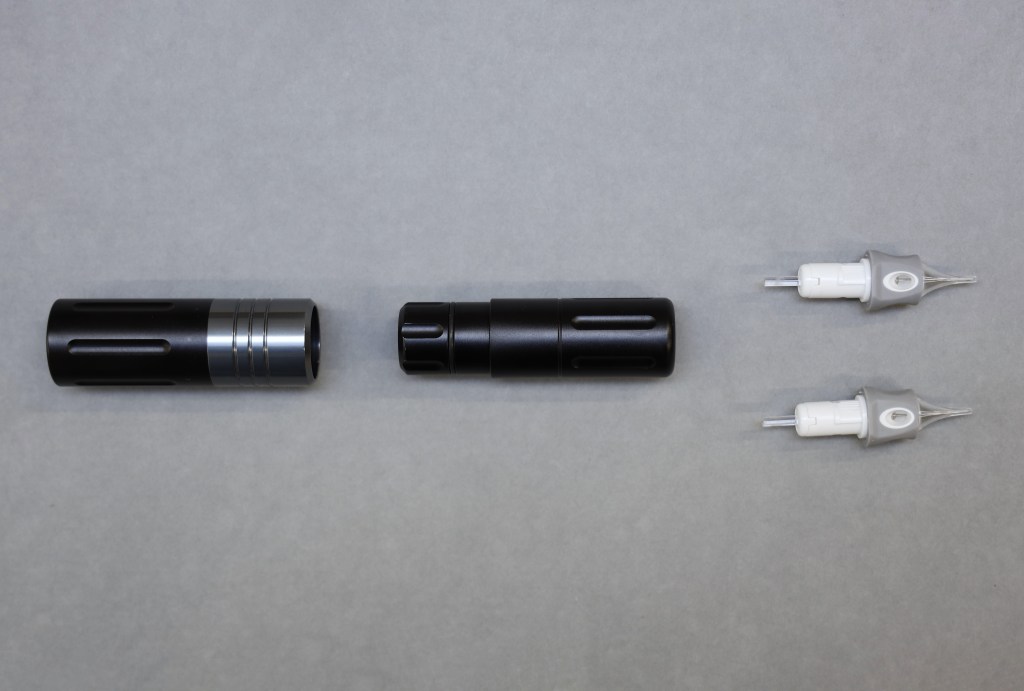

Tattoo pen

- Choose rotary tattoo pens from well-known, reliable brands that offer compatibility with a wide range of needle cartridges and quality after-sales service.

- Select a model with an integrated rechargeable battery, preferably USB-C, for universal charging and easy portability.

- The pen should allow for voltage adjustment, as well as needle depth control. Most models display the voltage on an LED or digital screen, with settings adjusted via a button or dial.

- Adjustable stroke length between 2.5 mm and 4 mm is ideal. A stroke that is too short will not pierce the paper without added pressure, while a stroke that is too long may damage the working surface under the paper.

- Choose a lightweight, ergonomic model (under 150 g, including the battery). Many professional tattoo pens are bulky, but certain models – especially those intended for permanent makeup and smaller hands – have a slimmer diameter and are more comfortable for extended use.

Needles

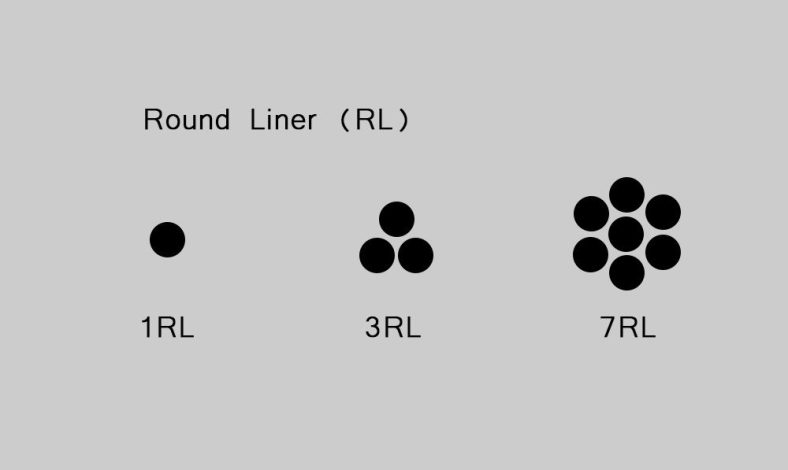

Needle grouping: Tattoo needle cartridges are categorised based on the arrangement of their tips. For conservation purposes, I recommend round liners (RL), ideal for producing clean, precise perforation lines. The needles are tightly grouped in a circular formation.

Number of tips: Configurations range from 1RL (single needle) to 3RL or 5RL, depending on the desired effect. Multi-tip configurations like 3RL create wider perforation lines that work well with heavier materials that have higher tear resistance.

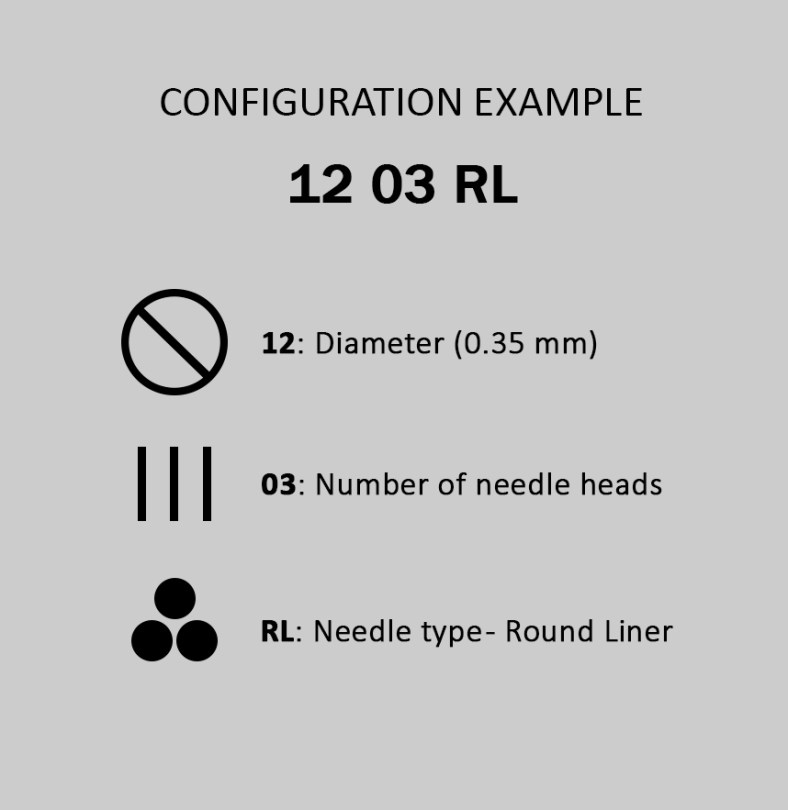

Needle diameter: Standard needles with a diameter of 0.30 mm or larger are preferable. Tattoo needles are usually extremely fine to avoid visible puncture marks on skin. However, in conservation, the goal is to create visible, controlled perforations – so standard or thick (in tattoo terms) needles are better. The diameter is measured in millimetres and typically coded with a standardised number (e.g., size #12 = 0.35 mm).

Soft membrane cartridges: These reduce vibration and ensure smooth needle motion, improving control and grip comfort. Usually they come with a silicone casing.

Working surface

Use a firm but slightly yielding surface to allow the needle to penetrate without slippage or damage. I recommend dense rubber plates made for block printing (lino carving blocks), available in various portable formats. These absorb the force of the needle for effective, clean puncturing. A regular cutting mat can also work, but the needle is more likely to break.

Standard workflow

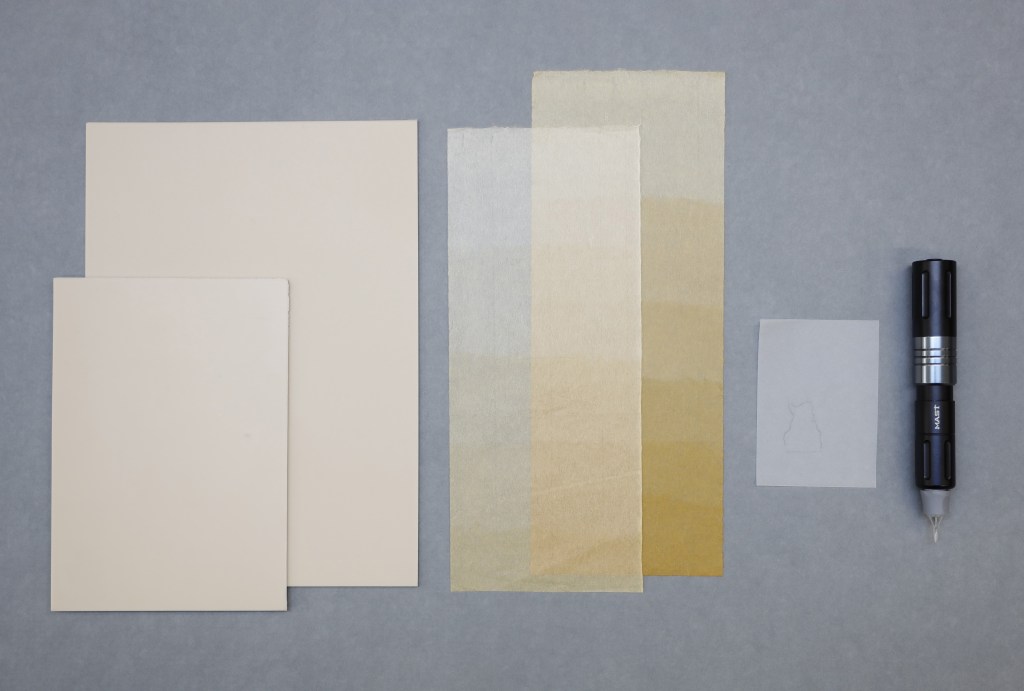

Start by tracing the required form onto Mylar®/Melinex® or tracing paper directly from the artifact. Select a suitable infill paper.

Supplies used

- Cordless Rotary Tattoo Pen with SMP Battery | Mast Nano

- 1201RL | Dragonhawk Glide Extra Smooth Tattoo Cartridges

- 1203RL | Dragonhawk Glide Extra Smooth Tattoo Cartridges

Alternative models from other reputable brands would also work if the configuration is similar.

Safety disclaimer

Sharp or pointed tools (such as scalpels, awls or needles) must always be handled with the utmost care. Ensure you are working in a safe, stable and well-lit environment. This tool is intended for use by trained professionals who are already familiar with the risks and safe handling of such instruments. The author cannot be held liable for improper or unsafe use.

Conclusion

The rotary tattoo pen has, I believe, found a rightful place in the toolkit of a paper conservator. To make the most of its potential, it is important to understand its technical features, which come from a field quite different from our own. I explored the world of tattooing to learn how these machines work, compare available models, and adapt that technical knowledge to find practical, user-friendly tools suited to our needs. These pens are efficient, precise and flexible – they can turn a repetitive, time-consuming task into a smoother, more controlled gesture. As long as you understand the settings and follow safety guidelines, they can be a helpful option for conservators looking to improve their working methods. I’ve had the chance to speak with many colleagues in French museums who have already started using a tattoo pen in their own projects, often with encouraging results. A few conservators from around the world have also reached out after seeing the tool on my Instagram page. They tested the pen and kindly provided positive feedback, particularly regarding the time it saved in their workflow. I’m grateful for these exchanges. From what I hear, this tool shows great promise in our field.

Acknowledgement

A special thanks to Angèle Brouté, intern at the Musée des Arts Décoratifs and final-year Master of Paper Conservation student at the University of Paris I, for kindly serving as the model for the demonstration. I also appreciate the support and willingness of my colleagues at MAD who agreed to take part in the testing process.

All photography and graphics by Anaïs Diez.

Anaïs Diez is a freelance paper conservator working with public institutions, who has extensive experience with nineteenth-century architectural drawings. A graduate of the paper conservation department at the Institut national du patrimoine (INP – National Institute for Cultural Heritage) in France, she specialises in the conservation of East Asian scroll paintings on silk and paper – a central focus of her research. Since 2023, she has been engaged in the study and conservation of the architectural drawings from the Pompeian House of Prince Napoleon at the Musée des Arts Décoratifs (MAD – Museum of Decorative Arts). She is regularly consulted for her expertise in working with challenging support materials, such as tracing paper.

One thought on “My Favourite Tool: Tattoo pen machines for paper infills – a game-changer for paper conservators”